|

New for 2008: The Revolutionary 19RCS Radial Brake Master Cylinder

Updated: Oct 25th, 2007

(c) OPP, 2007

Below is a copy of the official Brembo press release for the brand new 19RCS Radial Brake Master Cylinder and 16RCS Clutch Master Cylinder. It's a lengthy read so I'll summarize the main points. It's a really exciting product and it will be amazing for everyone ranging from racers, hardcore street riders, showbike creators to the average street rider. I would recommend this master cylinder and a set of Spiegler braided brake lines as the first upgrade to your brake system.

Update: The demand for the new master cylinders is high so please call us for more information or to backorder this part. We can be reached at 604-942-6744 or by emailing us at [email protected].

- The revolutionary aspect is the ability to choose between the 19x18 and 19x20 configuration. If you have read our An Overview of a Brembo Master Cylinder article, you will know what these numbers mean and that there is a trade-off between the two pivot configurations. Not to say that either configuration is bad, but the rider had to choose between varying degrees of feel and power. Now the rider can instantly change the configuration to suit their needs. No more compromises!

- Another unique aspect to this is the inclusion of a microswitch for the brake. In the past, one needed to install a banjo bolt with a pressure switch to activate the brake lights. Now, you will have the ability to hook up the stock brake electronics instead of using the aftermarket pressure switch.

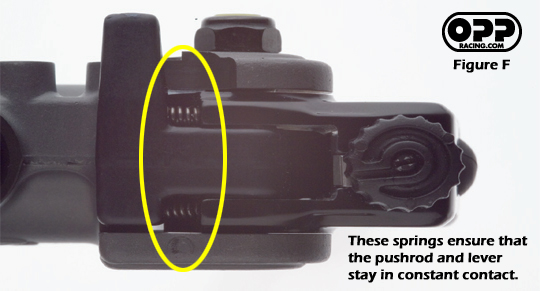

- For racers, the adjuster knob has been relocated to the same position as the 19x18 Billet Folding Brake Master Cylinder that is used by Valentino Rossi and Nicky Hayden in MotoGP and WorldSuperBike. Two springs have been installed to ensure constant contact between the lever and the pushrod to ensure a longer lifespan.

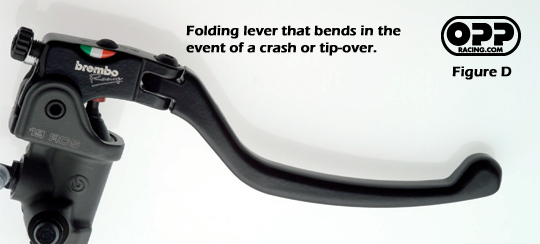

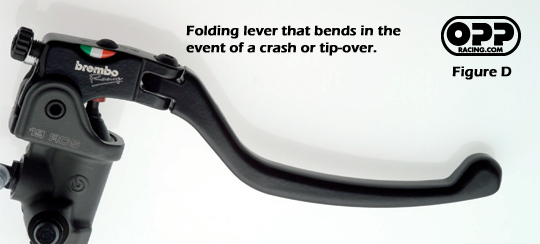

- The 19RCS brake master cylinder retains features that made Brembo the top brake system manufacturer today including forged CNC-machined construction and a folding lever that reduces crash damage.

Please read the official press release and click on the pictures for larger pictures of the master cylinder. If you have any questions, feel free to email us at [email protected] or call us at 604-942-6744.

Click here to purchase a 19 RCS Brake Master Cylinder or the 16 RCS Clutch Master Cylinder.

NEW BREMBO 19 RCS RADIAL BRAKE MASTER CYLINDER (OFFICIAL BREMBO PRESS RELEASE)

The Brembo radial master cylinder has effectively revolutionized motorcycle braking systems over the past ten years. Designed originally for use on Racing machines, it has become more and more popular over time for Super Sport, and even Naked bikes, while retaining the identity of an out-and-out racing component, still used today in MotoGP competition.

Today, bike enthusiasts everywhere can upgrade the braking system on their machines at a stroke, simply by replacing the production master cylinder with a Brembo radial, confident of the top-flight performance associated with many years experience acquired by the company in designing and engineering braking systems.

Why radial? The definition indicates a configuration whereby force can be transmitted to the piston in phase with the force applied by hand to the lever, eliminating the friction that would be generated if these forces were separated. In other words, the effort exerted by hand on the lever and the force applied by the lever to the piston are both generated in the same direction radially relative to the point where the cylinder is anchored, i.e. the handlebar. With this type of construction, the master cylinder can be designed with the focus on optimizing hydraulic and mechanical ratios, and consequently on improving its performance. This means that the force applied to the lever can be converted entirely into powerful, dependable and precise braking action.

For twin-disc systems; there are currently two models of Brembo radial master cylinder available: 19x18 and 19x20. The choice between the two models will be based essentially on the feel that the rider is able to get from the two solutions.

The 19x18 cylinder has better modulation, given its marginally longer operating travel when compared to the 19x20, which on the other hand offers a slightly quicker response.As a general rule, the 19x18 is recommended for bikes with 4-piston calipers (diameters 32/36, 34/34 and 30/34).

Brembo experience favours 19x18 for track, and 19x20 for street. Today, after 10 years as a brand leader, this legendary product has been updated with a number of significant new engineering features, all derived from MotoGP, and is now marketed as the new Racing radial brake master cylinder.

TECHNICAL DATA SHEET

The new Brembo 19 RCS radial brake master cylinder retains the familiar geometry, dimensions and functionality of the MotoGP component, while introducing many engineering improvements.

Adjustable Pivot Distance: RCS system

With this new patented device, the rider can set the brake lever pivot point at one of two distances, 18 or 20 mm, simply by turning a roller cam located on the front of the lever clevis. With the RCS Ratio Click System the change from one setting to another is simplicity itself, and the lever ratio can be adapted to the different characteristics of the braking system, the ride or the conditions: for example, dry or wet, road surfaces offering greater or lesser degrees of grip, riding style, and so on...

The red colour of the cam indicates pivot distance 18mm (FIG. C1), whereas the black colour indicates the 20mm position (FIG. C2). This is a feature that was until now unavailable, but now provides the adjustment that will give the optimum feel between rider, riding style, machine and circuit.

MOTO GP Piston Assembly

The piston, seals and push-rod are the same as those of master cylinders used by all riders in MotoGP and Superbike competition. In practice, MotoGP and Superbike provide the ultimate test-bed for these components, given the enormous stresses involved: late and hard braking, ultra-high disc temperatures... under these conditions, the rider must be able to rely on supreme dependability and unwavering efficiency of the braking system. The master cylinder plays a key role in the braking action, and with a MotoGP piston assembly fitted, top performance will be guaranteed whatever the conditions, thanks to the extremely close machining tolerances adopted, and a faultless sliding action within the cylinder body.

Master Cylinder Body

The body of the master cylinder is an aluminium alloy forging*, machined on CNC (Computer Numerical Control) equipment and weight-relieved by milling. Machining tolerances are extremely close. the same as adopted for MotoGP specification so as to guarantee a perfect match with the piston, and unparalleled stroking precision. The finish selected for the surface is hard anodization, an electrochemical process by which the surface of the aluminium and its alloys is converted into a layer of ultra-hard oxide. This durable film affords especially high resistance to abrasion and corrosion.

* The forging process involves preheating a cylindrical metal billet to a high temperature short of melting point, so that it remains solid then, using a press of several tonnes capacity, driving the hot metal into a die that presents the negative shape of the finished item.The main characteristic of a forged piece derives from the way the fibres of the material are oriented, and the influence this has on the mechanical properties of the component. Forging has the effect of orienting the fibres along lines parallel to the outer surfaces, a structural attribute that improves resistance to fatigue. Accordingly, the design of the die is fundamental, in that it must emulate the finished item. The smaller the differences between blank and finished part, the better the advantages of forging will be exploited.

Brake Lever

The brake lever is made up of two main components: the Racing Lever Clevis, and the lever itself, forged and hinged to the clevis.The clevis incorporates a patent system allowing angular movement only in the event that the bike should happen to fall or crash. This prevents the lever from rotating accidentally, and provides increased dynamic safety.

The lever span adjustment control has been repositioned and is now aligned with the lever, so that the adjuster can also be located remotely. Operating this control, the position of the lever contact face remains unchanged relative to the cylinder body, so that the optimum operating angle ß of the push rod can be maintained (see fig E). This means that the lever can be drawn closer to or distanced from the handlebar without any adverse effect on the mechanism, guaranteeing minimal friction and zero waste of energy. The technology is the same as adopted in MotoGP. In addition, the lever is hinged to the cylinder body by way of a precision pin and bush assembly, guaranteeing optimum rigidity, better feel and especially high resistance to wear.

Lever return springs

Two high load springs are used to ensure that the contact face and push-rod remain permanently engaged. This avoids the eventuality of wear through chatter that could be induced by vibrations from the machine, as well as introducing a further element of safety during the transition from throttle to brake, and generally prolonging the life of the various components.

Brake Light Switch

A housing has been included specifically to accept the mechanical switch of a brake light circuit, when the 19 RCS is set up for street use.

Clutch Master Cylinder

The 16RCS clutch master cylinder makes up a set with the 19RCS. The 16RCS is equipped similarly with the Ratio Click System, allowing adjustment of the feel on clutch control. Like the 19RCS brake master cylinder, this component has a forged aluminium alloy body with hard-anodized surface finish.

|