Your Account

Customer Service

[email protected]

|

View Cart (0) Your Account Customer Service [email protected] |

|

Brembo High Performance (HP): Build a Better Brake SystemUpdated: Jan 12th, 2009 (c) OPP, 2009 Table of Contents

Brembo is the best manufacturer of braking equipment in the world!!! If you think brakes, think Brembo! Even better, think Brembo and then think OPP! Whew, had to get that out of my system. But it's true, when it comes to upgrading your brake system from the stock components, the best choice is Brembo (and OPP Racing!). If you don't believe me, take a look at what is used in MotoGP or World Superbike. Taking a look at a Formula 1 or World Rally Championship car. When it comes to winning championships and getting the best performance, the only choice is Brembo (and www.oppracing.com!). Of course, it's unreasonable for you to blindly accept my endorsement. What makes Brembo the best choice? How will it help you and how will it improve your sportbike? The purpose of this article is educate you about Brembo's new High Performance division and to teach you about the components that you can use to make your bike perform better. At OPP, we make it a priority to educate our customers rather than taking advantage of their lack of knowledge about a product to sell stuff. As an official Brembo distributor, our team gets to communicate with Brembo technical staff and I have even had the opportunity to visit their main factory in Italy. I hope you find this article informative and entertaining.

In the past, Brembo's motorcycle division was divided into two divisions: OEM / Production and Brembo Racing. Brembo OEM / Production: This division manufactures Brembo components that can be found as OEM components on bikes. Examples include the master cylinders, calipers and rotors that you would find on most Italian sportbikes (ex. Ducati 1098) and the occasional Japanese sportbike (ex. Yamaha R1 or R6) and special edition sportbikes (ex. 2006 Yamaha R1 LE). These parts are designed for OEM and are not developed with aftermarket applications in mind. Part quality is good but they are built to cost so that the sportbike you buy off the floor is affordable. Brembo Racing: This division develops cutting-edge braking technology and provides the parts for elite racing series such as MotoGP and World Superbike. Billet monoblock calipers and carbon-carbon brake rotors are examples of products that are developed by this division. Top performance, regardless of cost. At this point, I need to clear up some misconceptions:

Brembo realized that there was a big gap between the two divisions in terms of performance and cost. As a racing privateer, track day enthusiast or average street rider, you had to choose between OEM / Production parts that were not much of an upgrade over stock or you had to jump up to Brembo Racing parts which were expensive, provided more performance than what was really needed, hard to get and somewhat difficult to install. So a few years ago, Brembo created a new division to address those concerns: Brembo High Performance.

Brembo High Performance (HP) was created to develop brake components that would be top quality, affordable, easy to install and available to the general public. How do they accomplish this?

As an official distributor, OPP orders direct from Brembo Italy and keeps everything in stock. If you have any questions about Brembo products, please contact us (info@oppracing or 604-942-6744) and we can get you the right answers. To be honest, you don't have to upgrade your brakes if you are just riding conservatively on the street. If the stock braking system on your sportbike wasn't good, it wouldn't be there. If it was not safe, it definitely wouldn't be there. There are a couple of reasons why you would want to upgrade your braking system.

Before we talk about how Brembo HP can improve your braking system, we need to know how the braking system works. A typical sportbike braking system is a hydraulic system that uses pressure from brake fluid to activate a system that will make the bike stop. When you squeeze the brake lever, it's going to make the brake pads grab onto your brake rotors and stop the bike. Let's follow the path of the fluid from the rider to the rotor and figure out what's happening. (As I have mentioned in other articles, I'm not an engineer and I won't get into the physics of how stuff works. I'm approaching this from the viewpoint of the average rider. I trust the Brembo engineers know what they are doing!) When the rider pulls on the brake lever, it pushes on a single piston in the master cylinder that forces brake fluid down the brake lines to the calipers. The calipers equally distributes the force of the brake fluid onto multiple pistons. These pistons push brake pads (friction material) that grab onto brake discs that are attached to the wheel. The friction from the brake pads and rotors will cause the bike to slow down but also generates a lot of heat. In order to understand what we can do with Brembo HP components, we break up the parts into the follow sections:

Along the way, I may mention other non-Brembo HP products. There may be instances where Brembo cannot provide a part or there may be other great alternatives available. I encourage you to learn more about those products on our website to see if they are suitable for your needs.

The brake master cylinder is one of the most popular components for upgrading because it's the only component that the rider uses to control the brake system. The response from pulling on the lever allows the rider to determine how the brake system is performing and how it changes under intensive use. The shape and set-up of the master cylinder lever plays a factor when considering ergonomics and how it fits into the rider's hand. For more information about Brembo master cylinders, I encourage you to read my article called "An Overview of a Brembo Master Cylinder". I also encourage you to read my enhanced press release called "New for 2008: The Revolutionary 19RCS Radial Brake Master Cylinder". It is the official Brembo press release regarding the Brembo 19RCS brake master cylinder with enhanced notes and images by OPP so you can understand it better.  Regarding brake master cylinders, Brembo HP offers a couple different choices. The flagship brake master cylinder is the 19RCS brake master cylinder. When Brembo designed the 19RCS master cylinder, they wanted to make a master cylinder that had every feature possible. I think they succeeded. Here is a summary of the features of the 19RCS master cylinder:

The 19RCS brake master cylinder and the matching 16RCS clutch master cylinder were introduced in November 2007 at the Milan trade show. Prior to that, there were other master cylinders available:

Upgrading your master cylinder will improve the feel and response of your brake system since the OEM master cylinder has some pretty conservative specifications. For example, let's say you were to upgrade the brake master cylinder of an R1 to a 19x20 forged master cylinder. The stock master cylinder is a 16x18 configuration. It has a smaller 16mm piston diameter and a more sensitive x18 interaxis value. The 19x20 master cylinder will push more brake fluid and have a more "powerful" lever set-up that will make the brake system feel more firm and effective. For track day enthusiasts and competitive racers, we recommend LighTech remote adjusters for Brembo when purchasing Brembo brake master cylinders. Remote adjusters, in general, allow riders to adjust the position of the brake lever using their left hand. This allows the rider to adjust for brake fade while riding - this is an important function the more you use your brake systems on the racetrack.

OPP Racing allow stocks a full line-up of Brembo HP billet clutch master cylinders for hydraulic clutch systems. These clutch master cylinders offer greater feel when engaging and disengaging the clutch. In this case, the 16RCS clutch master cylinder is a great compliment to the 19RCS master cylinder. Remember, the 16RCS and other Brembo clutch master cylinders only work with hydraulic systems so be sure to check your bike or ask your OPP sales representative to ensure that it will fit.

For bikes with a traditional cable clutch, consider using a LighTech folding cable clutch lever that offers adjustability, new ergonomics and has a folding lever.

When purchasing an aftermarket master cylinder, you will need to check that you will be able to put your brake system back together. Older motorcycles that have conventional (non-radial) master cylinders may have integrated fluid reservoirs that need to be replaced. If you replace your stock master cylinder, you will need to install a new remote brake fluid reservoir to carry extra brake fluid.  Brembo offers 4 different reservoirs: a 15ml reservoir with a straight mounting nozzle, a 15ml reservoir with a 45 degree angle mounting nozzle, a 30ml reservoir with a straight mounting nozzle and a 45ml reservoir with a 90-angle mounting nozzle.  You will need special tubing to connect your reservoir and master cylinder. Regular tubing will disintegrate when it comes in contact with brake fluid - the brake fluid leeches right through the tubing. When this happens, air can enter your brake system and cause it to fail. (Remember, air can be compressed. If you pull your brake lever, it would compress the air in the system rather than cause the caliper pistons to pinch your rotor. Your brake system won't work!). Brembo offers black, opaque tubing in their reservoir mount kits. OPP carries special transparent tubing as used by World Superbike teams. Functionally the same but more trick looking!  New for 2009! Brembo HP Reservoir Mounting Kits include a reservoir, mounting bracket, tubing and mounting hardware to connect your reservoir and master cylinder together. OPP Racing carries all of the reservoir sizes and transparent tubing so if you needed to make changes, we could add them to the kit. You can kits for both brake reservoirs and clutch reservoirs.  New for 2009! For owners of naked sportbikes, Brembo HP has special left master cylinder clamps and right master cylinder clamps that allow you to install your mirrors again. Like integrated reservoirs, mirror mounts may be built into the brake master cylinder. Installing this kit allows you to reinstall your mirrors without any problems. Ducati Streetfighter, here I come!  New for 2009! Finally, Brembo HP offers billet master cylinder clamps with red Brembo logos. Forged master cylinders like the 19x20 forged brake master or the 19RCS master cylinder come with a forged clamp with white lettering. For those that are fashion consciencous, this is for you!

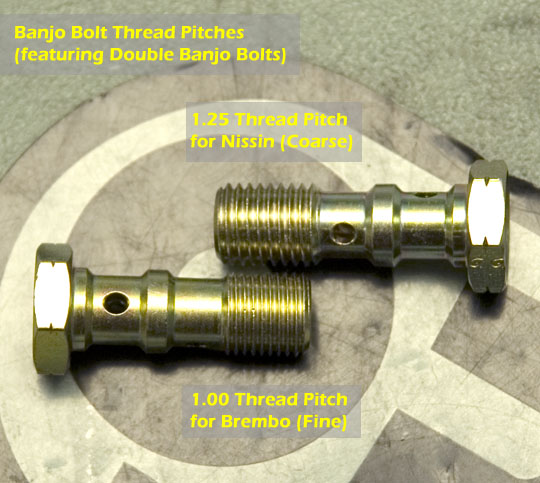

The next part of the brake system is brake lines and banjo bolts. Brake lines are important because they connect the master cylinder to the calipers. The configuration of the brake lines and the material used for construction are important as the brake lines need to conduct fluid efficiently. When I say efficiently, that means brake lines need to withstand the pressure created when the brake lever is pulled and conduct all of the force to the calipers without expansion. OEM brake lines are rubber and should be replaced with braided metal brake lines. I recommend you change the brake lines as soon as possible - the OEM rubber hoses need to be replaced at some point while braided brake lines will last forever. Installing braided brake lines will instantly make your brake system feel firmer. Since Brembo does not manufacture braided brake lines, OPP Racing recommends braided brake lines by Spiegler USA. Braided brake lines use a metal hose that is protected by a PVC cover. Braided brake lines do not expand and eliminate brake fade, can be custom-made for special applications and can be made with colored PVC hosing. Brake lines can come in a few configurations. On a sportbike with two front calipers, the standard configuration consists of a single brake line running from the master cylinder to right caliper and having a second, shorter brake line that connects the right caliper to the left caliper. Another standard configuration consists of a single line that runs from the master cylinder to a T-fitting that splits the line just above the front fender. The split lines run to each caliper. Finally, you can have two separate lines that run from the master cylinder to each caliper. If you need help figuring out what line configuration you have or what would be a good upgrade, you can call or email OPP Racing and we can discuss the details of your bike. Connecting brake lines to master cylinders and calipers is accomplished using banjo bolts. Banjo bolts are bolts that go through the metal fittings at the end of the brake lines and screw into the master cylinder or caliper. There are a few characteristics that need to be considered when selecting the correct banjo bolt.

Brembo brake calipers are probably the most fashionable brake components that you can install. The brake calipers serve several functions. Their main function is to transmit the force from the brake fluid to the brake pads efficiently and effectively. Calipers need to be able to transmit force equally among the brake pads to prevent uneven pad wear. Brake calipers also assist in dispersing heat that is generated from the braking friction and preventing it from being transmitted to the brake fluid. Remember, overheating your brake fluid reduces its effectiveness and will also cause rubber brake hoses to expand. There are certain characteristics that you need to know to understand the calipers. I'll use a set of Brembo Billet HP Calipers as an example.

Now that you know about the features and characteristics of a brake caliper, let's look at Brembo HP's Billet HP calipers and M4 Cast Monoblock calipers. Oh, but before you get to that, I forgot to mention a special new product from Brembo HP for 2009... New for 2009! OPP will be receiving the first Nickel-Cadmium Billet HP Calipers from Brembo HP! These are Billet HP Calipers with the shiny Nickel-Cadmium coating as seen as World Superbikes. Get them first, get them from OPP! Click on the pics below or click here to pre-order! And now, back to the regular article...  Billet HP Calipers: These are the first calipers to be introduced by Brembo HP. Each caliper is billet and has 4-pistons in a 30/34 configuration. They use two pads per caliper (which are included with each caliper) and are available in 100mm and 108mm spacings. 130mm mounting brackets are available for use with the 108mm calipers.  M4 Cast Monoblock Calipers: These calipers were first seen on the Ducati 1098 and were frequently described as powerful and phenomenal. Each caliper is cast and has 4-pistons in a 34/34 configuration, just like the flagship Brembo Racing P4P4 4-piston, 4-pad monoblock. They use two pads per caliper (which are included with each caliper) and are available in 100mm and 108mm spacings. Just like the Billet HP calipers, brackets are available to adapt the 108mm caliper to 130mm spacings. One feature you'll find only on Brembo HP calipers is an anti-chatter plate on the top of the caliper. It's visible on the top of the Billet HP Caliper. The anti-chatter plate is partially obscured by the triple bridge on the top of the M4 Cast Monoblock Caliper. The plate is designed to hold the brake pads in place and prevent them from rattling around. Professional racers don't care about the noise so long as the caliper helps them win races. Brembo HP realized that street riders would get irritated by the noise and developed the anti-chatter plate to control the noise.  New for 2009! OPP stocks the complete line of billet rear caliper kits for the 2008-2009 CBR1000RR, 2004-2008 ZX10R, 2007-2008 GSXR1000, 2007-2008 R1 and all Italian sportbikes (Aprilia, Ducati, MV Agusta, Bimota, Benelli, KTM and Moto Guzzi). Don't be fooled by the imitations that have been advertised on the internet for the last few years. Other companies have been packaging Brembo OEM rear calipers with crappy mounting brackets and passing them off as official Brembo rear caliper kits. These are the only rear calipers kits produced by Brembo HP. Brembo Billet Rear HP Calipers feature a 2-piston configuraton that uses two pads. They are CNC-machined like the HP front calipers and include the brake pads in the kit. Mounting brackets are included to position the caliper correctly but note that some caliper kits can only be used with aftermarket wheels.

One of the advantages of a Brembo HP caliper is that pads are included in the price of the caliper. This is a major cost savings for you. If you purchased a Brembo Racing caliper, you get only the caliper and pads are extra. Brembo HP brake pads are sintered (metallic) pads for road and race use. Extra brake pads can always be ordered from OPP. Another great choice for brake pads is Ferodo, a leader in friction materials. Ferodo features a range of brake pad compounds which include ST Sintergrip pads (like the Brembo pads), CP2.11 race pads and XRAC all-round brake pads. In special cases, OPP Racing sales representatives may recommend Ferodo pads. For example, BrakeTech's Ceramic Matrix Composite (CMC) brake rotors work exceptionally well with Ferodo CP2.11 pads as they have compatible friction compounds.

Brake rotors (or brake discs) are the final components to a good brake system. The value of a good brake rotor is not apparent until you actually consider what it does. The main purpose of the brake rotor is to use friction from the brake pads to stop your wheels from turning. This process involves a lot of force and generates a lot of heat. A brake disc can be broken down into the rotor (that interacts with the brake pads), the carrier (which attaches the rotor to the wheel) and the buttons (which connect the rotor and carrier together). Warpage and wear are issues that affect all brake rotors but show up sooner in inferior rotors. Over time, braking forces will cause the rotor to warp (not stay straight). A good rotor like a Brembo HP rotor will resist warpage much longer than an inferior brake rotor. The buttons that connect the rotor to the carrier will last longer too. Brembo HP rotors are made from high strength stainless steel and are constructed to last much longer than stock rotor. Brembo High Performance brake rotors are designed to disperse heat and gases. Brembo HP brake discs have a large number of buttons and a rotor design that channels heat away from the rotor, reducing heat transfer to the brake fluid. Brembo rotors also have holes drilled into the rotor in a specific way to disperse gases that build on the surface of the rotor during the braking process. You may notice that Brembo HP discs are round and don't look like a trendy wave rotor. The reason is that wave rotors and other cosmetic rotors are less effective and more prone to warpage than a traditional round rotor. Cutting away edges of the rotor reduces surface area for the brake pads to grab and make it easier for the rotor to flex and warp. I would not recommend this style of rotor for racing (except for the petal-style stainless steel rotors by BrakeTech). Perfect segue - another alternative that OPP highly recommends are BrakeTech rotors. BrakeTech specializes in brake rotor technology and has a few features that are not found in Brembo HP rotors. First, BrakeTech rotors feature a Cobra/Axis design that significantly reduces the stress put on the rotor buttons - the result is an exceptionally long lasting rotor. Second, BrakeTech rotors are available in stainless steel (like Brembo HP), iron rotors (for racing) or Ceramic Matrix Composites (CMC). Iron rotors have a higher coefficient of friction than stainless steel but are prone to rusting - recommended only for racing. CMC rotors are cutting edge ceramic rotors that offer race-spec performance but at street-level operating temperatures - these rotors are the top-of-the-line rotors available to the general public. Note that aftermarket rear rotors are not developed by Brembo nor BrakeTech. OPP currently offers stainless steel rear rotors made by Braking/Sunstar. You may recognize them from their involvement in World Superbike. These are great rotors and can be used with Brembo HP Billet Rear Caliper kits.

Upgrading your brake system can be pretty challenging at first glance, I've thrown a lot of information at you. To help clarify and direct you, I'll provide some of my recommendations for various situations.

Please remember that these are only general recommendations. It's important for YOU to decide what you want or need. If you're not sure if something will work with your bike, please ask us! We know a lot about Brembo and if we don't know the answer, we correspond directly with Brembo HP technical managers and product managers. Get the right answers from the right source! I hope that this article was informative and will help you decide which Brembo HP components are right for you. Better brakes are always a good investment. For racers, it's an advantage when hitting the corners. For street riders, anything that enhances safety is a priority in my books. For showbikes, Brembo billet parts are as sexy as they get. Feel free to ask us any questions about Brembo by emailing us at [email protected] or calling us at 604-942-6744. Back to the main articles library. |

|

||||||||||||

THIS ENTIRE SITE IS © 1999-2024 OPTIMUM PERFORMANCE PRODUCTS INC. PLEASE READ OUR COPYRIGHT AND LIABILITY STATEMENT

|

||||||||||||